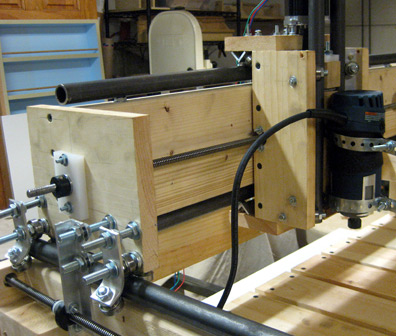

The next project I plan to tackle is a CNC machine, with a trim router as the cutter head. The laser engraver that I built last year was a sort of "trial run" for this project, as the laser engraver was smaller scale and cheaper, and only had two axes (compared to the three that the CNC machine will have). The plans I am following come from

Solsylva, and are quite detailed. Excited to get started!