Category: Other Projects

Just a Bit of Foolishness

Sign for the Workshop

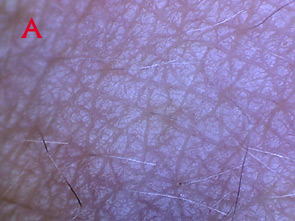

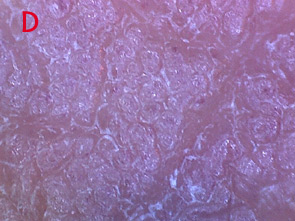

New Microscope

A: Back of the hand.

B: Fingertip.

C: Fingernail.

D: Elbow.

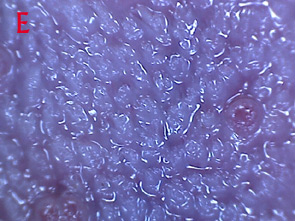

E: Tongue.

Random 3D Prints

Stuff I’ve Printed So Far

This next item is one of the first genuinely useful things I've printed. It's a clamp that lets the kids attach their tablets to the tripod when they want to make videos. It sure beats their old method of propping it up with books and hoping it doesn't fall over while they are recording.

Rock Tumbler

Leprechaun Trap

Little Raccoon

Bike Work Stand

Can I still call this a work 'stand' if it doesn't actually stand on the ground...? Lately I've been needing to adjust both my front and read derailleurs, and have been trying to figure out how to jury-rig a work stand without shelling out a couple of hundred bucks for a half-decent one. I read a few ideas online this morning, one of which mentioned that 3/4" black steel plumbing pipe is actually the exact same diameter as a seat post. Bingo! What I did was attach a 1" pipe flange to the main beam that runs through the garage, and I threaded a 30" x 1" pipe into it. At the end of this pipe is a 1" to 3/4" reducer coupling and then a 6" length of 3/4" pipe which I slide into the frame and clamp using the seatpost. It's very rigid and sturdy, and when I'm done working on the bike I can just unscrew the whole thing from the pipe flange and put it on a shelf!